Instrumentation & Control Systems: The Brains of the Operation

In the complex world of oil and gas processing, precise measurement, control, and monitoring are essential for safe, efficient, and optimized operations. This is where instrumentation and control systems (I&CS) come into play. They act as the central nervous system of oil and gas facilities, providing real-time data and allowing for automated control of various processes. Here's a breakdown of the key components within I&CS:

1. Pressure Gauges & Transmitters:

Pressure Gauges: These devices provide visual indications of pressure at various points within a system. They come in analog and digital formats, allowing for real-time monitoring by operators..

Pressure Transmitters: These instruments convert pressure readings into electronic signals that can be transmitted to control systems. They offer greater accuracy and facilitate data logging and automated control based on pressure variations..

2. Flow Meters & Controllers:

Flow Meters: Measuring the flow rate of oil, gas, water, and other fluids is crucial for production optimization and accounting. Positive displacement meters and Coriolis meters are commonly used technologies, each suited for specific applications..

Flow Controllers: These automated systems regulate the flow rate of fluids within pipelines or processes. They utilize control valves and adjust their opening based on feedback signals from flow meters, maintaining desired flow rates and optimizing production..

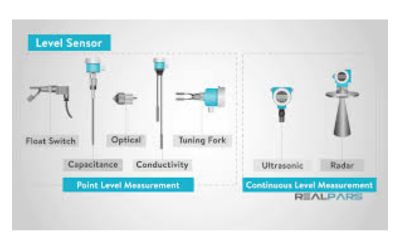

3. Level Sensors & Switches:

Level Sensors: These devices continuously monitor the level of liquids or solids in tanks, vessels, or pipelines. Radar level gauges and ultrasonic level meters are commonly used, providing accurate level data for process control and inventory management..

Level Switches: These act as on/off triggers based on liquid level reaching a predetermined point. They can be used for alarms, pump control, or process safety functions, ensuring tanks are not overfilled or emptied beyond safe operating limits..

4. Data Acquisition & Control Systems (SCADA):

Supervisory Control and Data Acquisition (SCADA): This is the central hub of the I&CS network. SCADA systems collect real-time data from various sensors and instruments throughout the facility. They allow for:

-Visualization: Operators can view real-time process parameters on a central screen, monitoring pressure, temperature, flow rates, and other critical data..

-Alarm Management: SCADA systems can trigger alarms in case of abnormal readings, alerting operators to potential issues or safety hazards..

-Data Logging & Historical Analysis: SCADA systems record process data over time, allowing for historical analysis, performance optimization, and troubleshooting.

Programmable Logic Controllers (PLCs): These are specialized industrial computers used for automated control of specific processes within a facility. They receive input signals from sensors and activate control valves, pumps, or other equipment based on pre-programmed logic.

Distributed Control Systems (DCS): For large and complex facilities, DCS offer a higher level of control. They consist of a network of interconnected PLCs and computers that manage various plant operations in a coordinated manner, providing a comprehensive overview and control of the entire process.

By utilizing a robust I&CS infrastructure, oil and gas companies can achieve:

Improved Efficiency: Real-time data and automated control optimize processes, leading to increased production efficiency and reduced waste.

Enhanced Safety: Continuous monitoring and automated safety features help prevent incidents and ensure safe operation.

Reduced Costs: Improved efficiency and fewer operational upsets translate to reduced overall operating costs.

Optimized Production: Data analysis allows for informed decision-making, leading to better production planning and resource allocation.

In conclusion, instrumentation and control systems play a vital role in the oil and gas industry, ensuring safe, efficient, and optimized operations from drilling and production to processing and refining.