Transportation & Storage: The Journey from Wellhead to Market

Once extracted from the wellbore, oil and gas need to travel a significant journey before reaching their final destination. The transportation and storage sector plays a critical role in this vital process, ensuring the safe, efficient, and reliable movement and containment of these valuable resources. Here's a breakdown of the key categories after the piping stage:

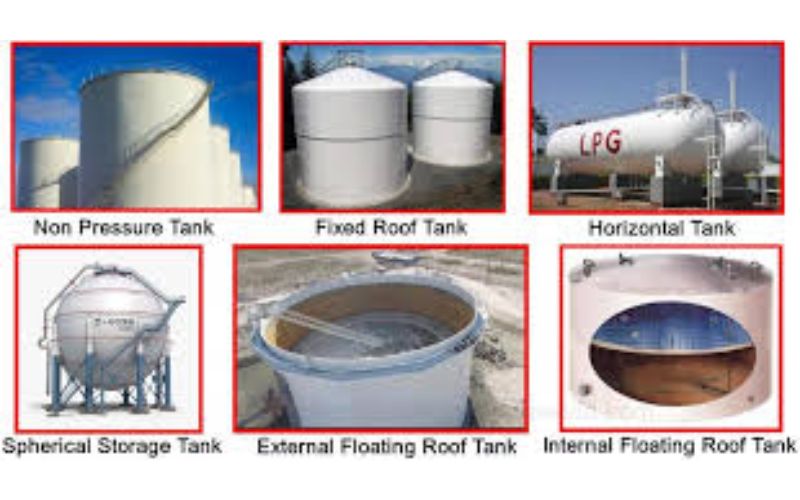

1. Storage Tanks:

Storage tanks play a crucial role in managing the flow of oil and gas throughout the supply chain. These large vessels provide temporary or long-term storage for crude oil, refined products, and liquefied natural gas (LNG).

Here are the two main types:

Aboveground Storage Tanks (ASTs): These are typically large, cylindrical tanks made of steel and located onshore at refineries, terminals, or production facilities.

They are used for the storage of crude oil, refined products like gasoline and diesel, and LPG (liquefied petroleum gas).

Underground Storage Tanks (USTs): These are smaller tanks buried underground, often used for storing gasoline and diesel at gas stations.

They are subject to stricter regulations due to environmental concerns.

2. Pumps & Compressors:

The movement of oil and gas through pipelines requires overcoming friction and pressure drops.

Pumps and compressors provide the necessary energy boost to keep the product flowing:

Centrifugal Pumps: These are common for transporting liquids like crude oil and refined products.

They use rotating impellers to convert kinetic energy into pressure, pushing the fluids through the pipeline.

Reciprocating Compressors: These are essential for transporting natural gas over long distances.

They use pistons to compress the gas, increasing its pressure and allowing for more efficient transportation through pipelines.

3. Metering & Instrumentation:

Accurate measurement of the quantity and flow rate of oil and gas is crucial throughout the transportation and storage process.

Here are some key instruments:

Flow Meters: These devices measure the volume or mass of oil, gas, or refined products flowing through a pipeline.

Different technologies like positive displacement meters and Coriolis meters are used based on the specific application..

Pressure Gauges: Monitoring pressure within pipelines is essential for ensuring safe operation.

These gauges provide real-time data on pressure fluctuations and help prevent pipeline ruptures.

Level Instruments: These instruments, like radar level gauges or ultrasonic level meters, measure the level of liquids stored in tanks,

ensuring optimal storage capacity utilization and preventing overfilling.

By utilizing this comprehensive network of transportation and storage infrastructure, oil and gas companies can efficiently move their products from wellhead to market, ensuring a reliable and steady supply of energy to consumers worldwide.